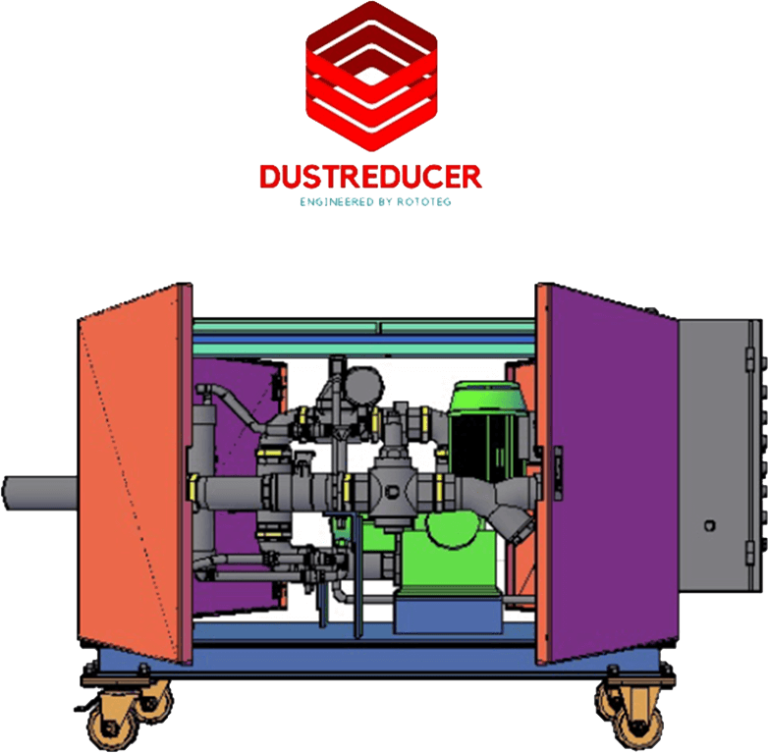

Dust Collector is a dust or smoke suction machine for industrial processes. In industrial processes such as pouring material, welding, sifting flour, the process of falling material from conveyor to another conveyor, and several other important applications that cause dust and smoke to be inhaled by a dust collector machine. The dirty air then filtered and separated between dust and air, dust enters the shelter while the air is discharged outside the factory so that air pollution can be overcome.

Our effective, low cost solution integrate customized levels of operational control while helping you meet governmental regulations, reduce housekeeping costs and increase operational efficiency.

Application:

Benefits:

When sitting for long periods of time, coals, such as those from Indonesia and the Powder River Basin have the tendency to self heat. This creates the possiblity of hot spots and fires. CHEMPO, a blend of chemicals, stabilizes coal and reduces spontaneous heating during transport and storage, minimizing risk and safety concerns. The result is less risk and a safer operation with no effect on the coals performance.

ROTOTEG TOTAL SOLUSI, was established with the main business to fulfill the demand of bulk material handling high quality products.